Your inventory reports are wrong, costing you sales and tying up cash. This chaos feels unavoidable. A reliable 3PL partner1 provides the control you need to stop these profit-draining mistakes.

A professional 3PL manages inventory using a Warehouse Management System (WMS)2 as a central brain. This system, combined with strict inbound receiving controls3, regular cycle counts4, and real-time visibility5, ensures that what the system says you have is what you actually have on the shelf.

As someone who has managed logistics for U.S. importers for years, I've seen where things go wrong. Inventory problems rarely start at the warehouse shelf. They begin much earlier in the supply chain6, often before your container even leaves China. Understanding how a top-tier 3PL manages this process is the first step to protecting your business from costly stock errors. Let's break down how the best 3PLs maintain control and how you can avoid the common pitfalls that trip up so many importers.

How Do 3PLs Manage Inventory for U.S. Importers?

Your container lands, but you have no real visibility into your stock. This uncertainty leads to shipping delays7 and frustrated customers. A modern 3PL gives you complete control and clarity.

3PLs use a Warehouse Management System (WMS)2 to track every item. They enforce strict inbound receiving protocols8, perform regular cycle counts4 to verify stock, and provide you with a real-time portal to see exactly what you own and where it is located.

A 3PL’s ability to manage inventory rests on a foundation of technology and process. It's not magic; it's discipline. The goal is to create a single source of truth for your stock levels, from the moment your container is opened at the warehouse door until a final order ships to your customer.

The Warehouse Management System (WMS)2 is the Core

The WMS is the brain of the entire operation. It's far more than a simple spreadsheet. It tracks every single unit of your inventory by assigning it a unique location in the warehouse, like a digital address. When your container arrives from China, each carton is scanned and received into the WMS against your purchase order. When an order is placed, the WMS directs a warehouse worker to the exact location for picking. This technology eliminates guesswork and minimizes human error. It provides the data for every other process, from cycle counting9 to reorder point planning. Without a robust WMS, accurate inventory management is impossible.

Inbound Receiving: The First Line of Defense

Most inventory errors begin at the receiving dock. This is why a disciplined inbound process is critical. When your Full Container Load (FCL) arrives from a port like Shanghai, our team doesn't just start unloading. We first verify the container and seal numbers against the shipping documents. During the devanning (unloading) process, each carton is counted and inspected for damage. We check this physical count against the packing list you provided. If there is a discrepancy—say, the list shows 500 cartons but we only count 498—we stop, document the issue with photos, and notify you immediately. This prevents a phantom "two cartons" from haunting your inventory records for months.

How Do 3PLs Prevent Stockouts and Overstocking?

You're constantly struggling with either having too much product or not enough. Both of these problems destroy your profit margins and damage your brand's reputation. A data-driven 3PL helps you find the right balance.

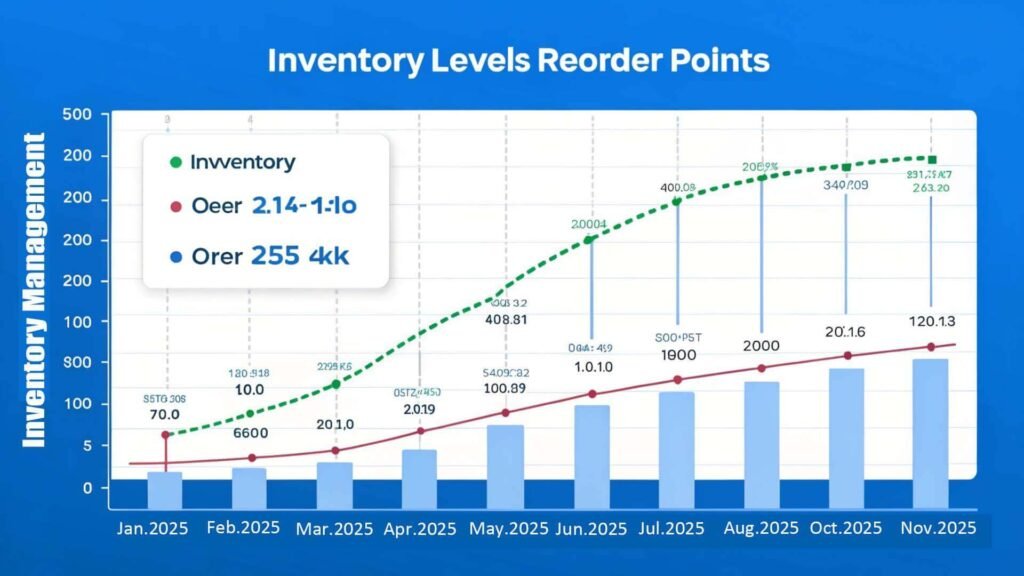

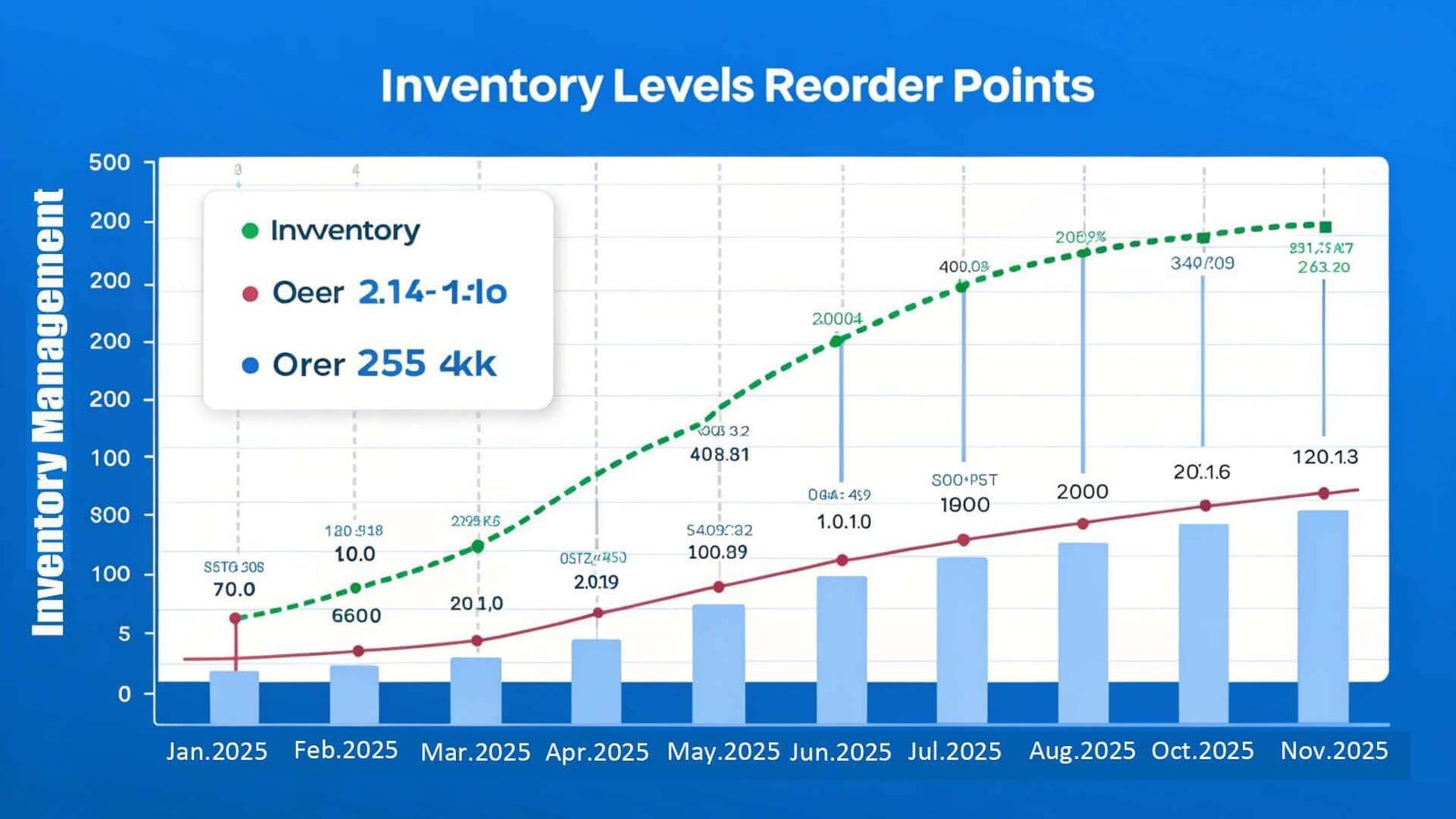

A good 3PL helps prevent these issues by using WMS data to establish demand forecasts10, optimal reorder points11, and safety stock levels12. This data-driven approach ensures you have enough inventory to meet demand without tying up unnecessary cash in excess stock.

Preventing stockouts and overstocking is about turning historical data into future action. A 3PL shouldn't just store your goods; they should provide the insights you need to manage your inventory investment wisely. We work with importers to build a strategy that protects cash flow while ensuring you can always fulfill customer orders. This process involves a few key pillars that transform inventory from a liability into a well-managed asset.

Using Data for Smart Decisions

Your WMS contains a goldmine of information. It shows how quickly specific products sell, identifying your bestsellers and your slow-movers. We use this data to help you with:

- Demand Forecasting: By analyzing past sales velocity, we can help you project future demand, especially for seasonal items. This prevents you from ordering too much of a product after its peak season has passed.

- Reorder Points: We help you calculate the exact inventory level that should trigger a new order from your supplier in China. This calculation is crucial and must account for the entire lead time: production time, ocean freight transit, customs clearance13, and warehouse receiving.

Here is a simple table to show how it works:

| Metric | Description | Example Value |

|---|---|---|

| Average Daily Sales | Units sold per day | 20 units |

| Total Lead Time | Days from order to warehouse | 50 days |

| Safety Stock | Buffer for delays | 200 units (10 days) |

| Reorder Point | (20 units/day * 50 days) + 200 units | 1,200 units |

When your stock for this item drops to 1,200 units, the WMS can send an automatic alert. This data-driven trigger ensures you reorder at the perfect time to avoid a stockout.

What Is the Gold Standard for Inventory Accuracy in a 3PL Warehouse?

Your 3PL's reports claim you have 500 units, but only 480 are actually on the shelf. These hidden discrepancies cause fulfillment failures, backorders, and angry customers. You must demand a higher standard.

The gold standard for inventory accuracy is 99.5% or higher. This benchmark is achieved through disciplined cycle counting9 programs, strict process controls, and transparent Key Performance Indicators (KPIs). Anything less introduces significant risk to your business operations.

Inventory accuracy is not a vague goal; it is a measurable KPI that separates professional 3PLs from amateur operations. An accuracy rate of 95% might sound decent, but it means that 1 out of every 20 inventory records is wrong. For an importer with thousands of units, this translates into dozens or even hundreds of errors. These errors create a ripple effect, leading to incorrect stock levels on your e-commerce store, promising products to customers that you don't actually have, and wasting time and money on manual recounts. A reliable 3PL partner1 understands that near-perfect accuracy is a non-negotiable requirement for a healthy supply chain6.

Measuring What Matters: Key KPIs

We measure accuracy using a metric called Inventory Record Accuracy (IRA)14. It's calculated with a simple formula: (Number of Items with Accurate Counts / Total Number of Items Counted) x 100. To achieve a high IRA, we rely on a process called cycle counting9. Instead of a disruptive, once-a-year physical inventory count, we count small sections of the warehouse every single day. This continuous verification catches discrepancies early and allows us to investigate the root cause while the trail is still fresh. Was it a receiving error? A mis-pick? A system glitch? Continuous improvement is only possible when you have continuous measurement. We hold ourselves accountable to this 99.5%+ standard and are transparent with our clients about our performance.

How Can Importers Avoid Inventory Errors When Working With a 3PL?

You blame your 3PL for inventory mistakes, but the problem often starts with your supplier. This endless cycle of finger-pointing is expensive and solves nothing. You can break the cycle by controlling your inbound process.

Importers can prevent most errors by providing a 100% accurate packing list and an Advance Shipping Notice (ASN)15 before a container arrives. Aligning all documentation and ensuring your supplier labels cartons correctly are critical for a clean warehouse handoff.

As an importer, you have more control over inventory accuracy than you think. The most frequent and frustrating errors we see all trace back to problems that occur before the goods even reach our U.S. warehouse. A 3PL can have the world's best systems, but they can't fix fundamental issues that begin at the source. Garbage in, garbage out. By taking ownership of a few key steps in the import process, you can set your 3PL partner1 up for success and virtually eliminate the most common inventory errors.

Your Process Starts at the Factory

The foundation of inventory accuracy is clear communication and perfect documentation.

- Demand an Accurate Packing List: The packing list from your supplier in China is the foundational document for inventory receiving. It must be perfect. It needs to clearly state the contents of each master carton, including SKU, description, and quantity. Any errors on this list will be imported directly into the WMS, creating discrepancies from day one.

- Send an Advance Shipping Notice (ASN)15: An ASN is an electronic version of your packing list that you send to your 3PL before the shipment arrives. This allows the warehouse to prepare for your delivery by loading the data into the WMS ahead of time. When your container arrives, the team simply scans the cartons, and the system verifies the contents against the ASN data. This makes receiving faster and far more accurate.

- Coordinate Your Customs Broker and 3PL: Your U.S. customs broker and your 3PL must be in communication. Customs clearance delays can disrupt warehouse receiving schedules. A coordinated team, like the one we provide with our integrated customs brokerage16 and logistics, ensures a seamless transition from the port to the warehouse, preventing delays that can throw inventory planning into chaos. Even when using DDP shipping17, where we manage the entire process, providing this accurate upfront information is essential.

Conclusion

Accurate 3PL inventory management is not a luxury. It is the core requirement for predictable cash flow18, reliable order fulfillment19, and a scalable import business20 that you can trust.

Understanding the role of a 3PL partner can help you streamline your inventory management and reduce costly errors. ↩

Learn how a WMS can transform your inventory management by providing real-time data and reducing human error. ↩

Explore how strict inbound receiving controls can prevent inventory discrepancies and improve accuracy. ↩

Understand how regular cycle counts can help maintain accurate inventory records and prevent errors. ↩

Discover the benefits of having real-time visibility into your inventory to avoid stockouts and overstocking. ↩

Learn how issues in the supply chain can lead to inventory problems and how to mitigate them. ↩

Find out how shipping delays can disrupt inventory levels and customer satisfaction. ↩

Explore how these protocols ensure accurate inventory records from the moment goods arrive. ↩

Learn why cycle counting is a more efficient and accurate method for maintaining inventory accuracy. ↩

Discover how demand forecasts can optimize inventory levels and prevent stockouts or overstocking. ↩

Learn how setting accurate reorder points can ensure timely restocking and prevent stockouts. ↩

Understand the importance of maintaining safety stock levels to buffer against unexpected demand. ↩

Understand the impact of customs clearance on inventory timelines and how to manage it effectively. ↩

Explore how IRA is a critical KPI for maintaining accurate inventory records and fulfilling orders. ↩

Find out how an ASN can streamline the receiving process and improve inventory accuracy. ↩

Learn how integrated customs brokerage can streamline the import process and prevent delays. ↩

Discover how DDP shipping can simplify the import process by managing all logistics and duties. ↩

Explore how maintaining accurate inventory records can stabilize cash flow and support business growth. ↩

Understand how precise inventory management ensures timely and accurate order fulfillment. ↩

Learn how effective inventory management practices can enable business growth and scalability. ↩