Slow, unpredictable deliveries are hurting your business and costing you customers. The solution starts with understanding what e-fulfillment1 really is, beyond the simple act of shipping a package.

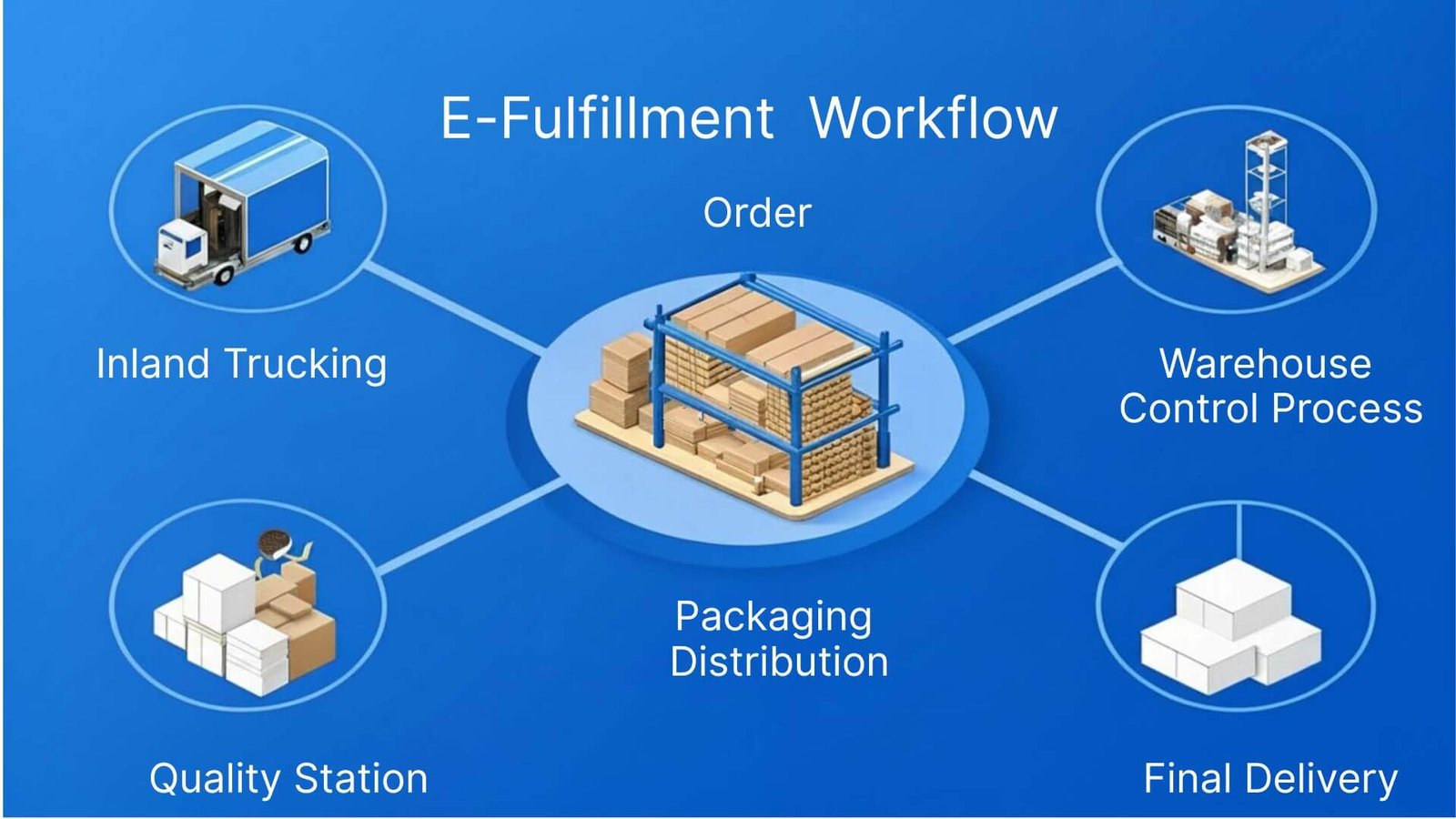

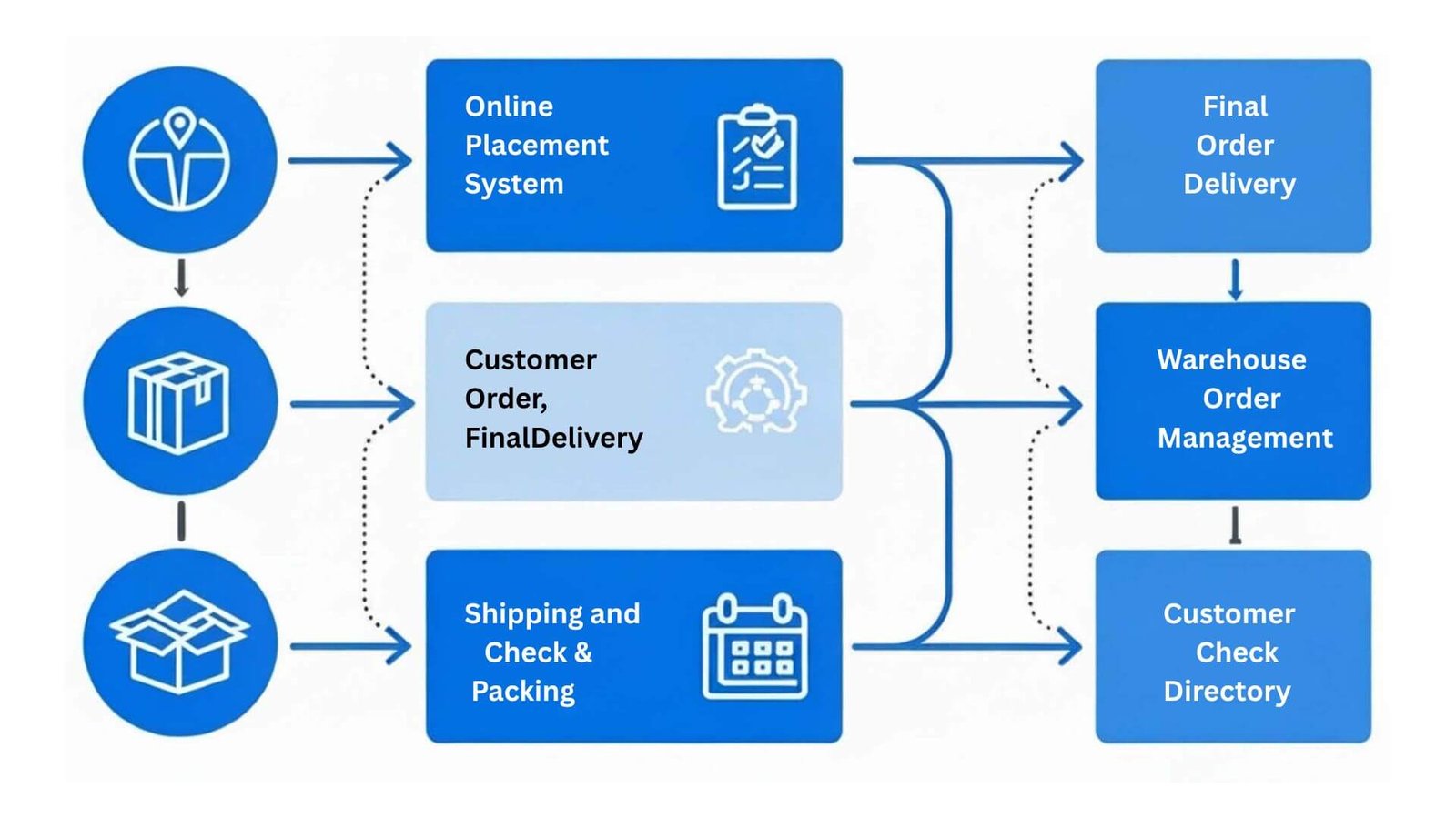

E-fulfillment is an integrated system2 combining warehousing, order processing, and shipping3 to manage online sales. It speeds up delivery by streamlining the entire process from the moment your bulk inventory arrives until an individual order reaches your customer's door, minimizing delays at every step.

When I talk to U.S. importers like Mark, who are experts in their products but frustrated with logistics, the conversation often turns to delivery speed4. They see speed as the final step—the carrier's transit time. But the real gains, and the worst delays, happen long before a box is ever handed to a courier. True e-fulfillment1 is about designing a seamless system5 that connects your factory in China to your customer's doorstep in the USA. It's about building a process that's fast because it's predictable and efficient from the very beginning. Let's break down how this system works and how you can use it to gain a competitive edge.

E-Fulfillment Explained: How Do Integrated Warehousing, Order Processing, and Shipping Work Together to Accelerate U.S. Delivery?

Confused by logistics jargon? Fulfillment, shipping, and delivery sound similar, but treating them as the same thing costs importers time and money. Here is the clarity you need.

E-fulfillment is a dynamic system where warehousing, order processing, and shipping3 are synchronized for e-commerce. Unlike traditional warehousing for bulk storage, e-fulfillment1t center](6s">https://flexlogistics.com/news/understanding-fulfillment-centers-the-backbone-of-ecommerce-logistics)6s are designed to immediately receive, process, and ship individual online orders from your imported inventory, accelerating the final delivery.

For U.S. importers, the distinction is critical. You aren't just storing pallets; you're positioning inventory for immediate sale. The goal of an e-fulfillment1 system is to shrink the time between a customer's click and their package's arrival. This requires a different mindset and a different operational flow than traditional logistics. I've seen many businesses invest in fast last-mile shipping, only to be hamstrung by slow, disconnected processes upstream. The key is to see e-fulfillment1 as a single, integrated engine, not a series of separate services.

Fulfillment vs. Shipping vs. Delivery

Understanding these terms is the first step to controlling your supply chain7. For an importer, they represent distinct stages with different risks and costs.

- Fulfillment: This is the complete process of handling an order inside the warehouse. It includes receiving and storing your inventory, picking the correct items for an order, packing them securely, and labeling the package for shipment.

- Shipping: This is the specific action of handing the packed and labeled order to a carrier (like UPS, FedEx, or USPS) for transport. This is a single event within the larger fulfillment process.

- Delivery: This is the final leg of the journey where the carrier transports the package from the fulfillment center6 to the customer's final address.

A failure in fulfillment, like a slow picking process, directly delays shipping, which in turn delays the final delivery.

From Container to Customer: The E-Fulfillment Flow

Think of your full container load (FCL) arriving from China. In a traditional model, that container might sit at port, then get moved to a storage warehouse where it waits for a bulk buyer. In an e-fulfillment1 model, the process is built for speed: your FCL container is immediately drayed to an e-fulfillment1t center](https://flexlogistics.com/news/understanding-fulfillment-centers-the-backbone-of-ecommerce-logistics)%%%FOOTNOTE_REF_6%%%, its contents are unloaded, scanned into the Warehouse Management System (WMS)8, and made available for sale online within hours. When a customer places an order, the system instantly directs a warehouse associate to pick, pack, and ship it. This seamless flow from bulk import to individual order is the core of modern e-fulfillment1.

Why Does E-Fulfillment Speed Depend on Import Strategy, Customs Clearance, and Inventory Positioning — Not Just Last-Mile Shipping?

Your orders are stuck, but your fulfillment center6 blames the carrier. The real problem likely started weeks ago with a customs issue. You must look at the entire supply chain7.

E-fulfillment speed is determined by your end-to-end import strategy, not just last-mile shipping. Delays caused by customs holds, incorrect HS code classification, port congestion9, and poor inventory positioning10 create the biggest bottlenecks, stopping your products before they even reach the fulfillment center6.

I always tell my clients that the fastest fulfillment starts on the other side of the ocean. Paying for expedited last-mile shipping is a waste of money if your container is held by U.S. Customs for two weeks. The most successful importers I work with focus on creating a predictable, uninterrupted flow of goods. They understand that a container that clears customs smoothly and is positioned in the right warehouse close to their customer base will always lead to faster delivery times than a container that faces unexpected hurdles, no matter how fast the final courier is. Speed is a result of control and planning across the entire import journey.

The Hidden Bottlenecks Before Your Warehouse

Many importers focus entirely on the 3PL or fulfillment center's performance11xlogistics.com/news/understanding-fulfillment-centers-the-backbone-of-ecommerce-logistics)6's performance, but the costliest delays happen earlier.

- Customs Holds: A simple paperwork error, a misclassified HS code, or a random inspection can lock up your inventory for days or weeks. Your fulfillment center6 can't ship what it doesn't have.

- Port Congestion & Drayage: Choosing a congested port can add a week or more to your timeline. Even after your container is off the ship, securing a truck for drayage to the warehouse can cause significant delays if not planned properly.

- Inventory Positioning: Shipping from a single warehouse in California to a customer in New York is slow and expensive. A smart import strategy involves positioning inventory in multiple fulfillment center6s across the country based on sales data.

How DDP Shipping Creates Predictability

This is where a Delivered Duty Paid (DDP)12 shipping model becomes a powerful tool for e-fulfillment1. As your customs broker and forwarder, I handle the customs clearance13 process while your container is still on the water. By the time the vessel docks in the U.S., your entry is already cleared with Customs and Border Protection (CBP). This means there are no delays at the terminal. The container can be picked up immediately and moved directly to the fulfillment center6. This DDP-integrated approach transforms your supply chain7 from a series of reactive, uncertain steps into a predictable, proactive system designed for speed.

What Is The End-to-End E-Fulfillment Workflow for U.S. Importers, from Factory Pickup to Same-Day Order Dispatch?

Mapping your supply chain7 feels impossible when you lose track of goods between the factory and your warehouse. I can show you the complete, integrated workflow that saves time and money.

The end-to-end e-fulfillment workflow14//www.shipbob.com/blog/e-fulfillment/)1 workflow starts with cargo pickup from the factory in China and FCL ocean transport. Upon U.S. arrival, goods are pre-cleared through customs, moved to a fulfillment warehouse, and are immediately available for picking, packing, and dispatching to final customers.

For a U.S. importer, visibility and control are everything. The ideal workflow is not a chain of disconnected partners but a single, fluid pipeline. When you manage the entire process under one umbrella, you eliminate the communication gaps, paperwork errors, and surprise delays that plague so many businesses. I've built my services around this principle. By managing everything from the factory floor in China to the customs entry in the U.S. and the final order dispatch, we provide clients like Mark with a level of control they've never had before. This turns a complex international process into a manageable, predictable operation.

A Step-by-Step China to USA DDP Workflow

Here’s how an optimized, end-to-end e-fulfillment1 process looks for an FCL shipment from China:

- Factory Pickup & Port Consolidation: Your goods are picked up from the manufacturer in China and transported to the port.

- FCL Ocean Transit: The container is loaded onto a vessel destined for the U.S.

- In-Transit U.S. Customs Clearance: While the vessel is at sea, I file the customs entry using the shipping documents. We resolve any issues with CBP before the ship even docks.

- Port Arrival & Drayage: Once the container is discharged, it's already cleared. We schedule a truck to immediately move it from the port to the designated e-fulfillment1t center](https://flexlogistics.com/news/understanding-fulfillment-centers-the-backbone-of-ecommerce-logistics)%%%FOOTNOTE_REF_6%%%.

- Warehouse Inbound & Inventory Sync: At the fulfillment center6, the container is unloaded, and every item is scanned into the Warehouse Management System (WMS)8. Your online store's inventory is updated in real-time.

- Order Fulfillment: When a customer places an order, it is automatically sent to the WMS. The system generates a pick list, and a warehouse associate picks, packs, and labels the order for shipment.

- Same-Day Dispatch: The package is handed off to the carrier for delivery to the end customer.

Where Importers Lose Control and Money

The biggest points of failure occur during the handoffs: from the factory to the freight forwarder, from the forwarder to a separate customs broker, and from the broker to a disconnected 3PL warehouse. Each handoff is a risk for delays, lost paperwork, and miscommunication. An integrated DDP fulfillment model eliminates these handoffs, creating a single line of accountability and a much smoother, faster path for your inventory.

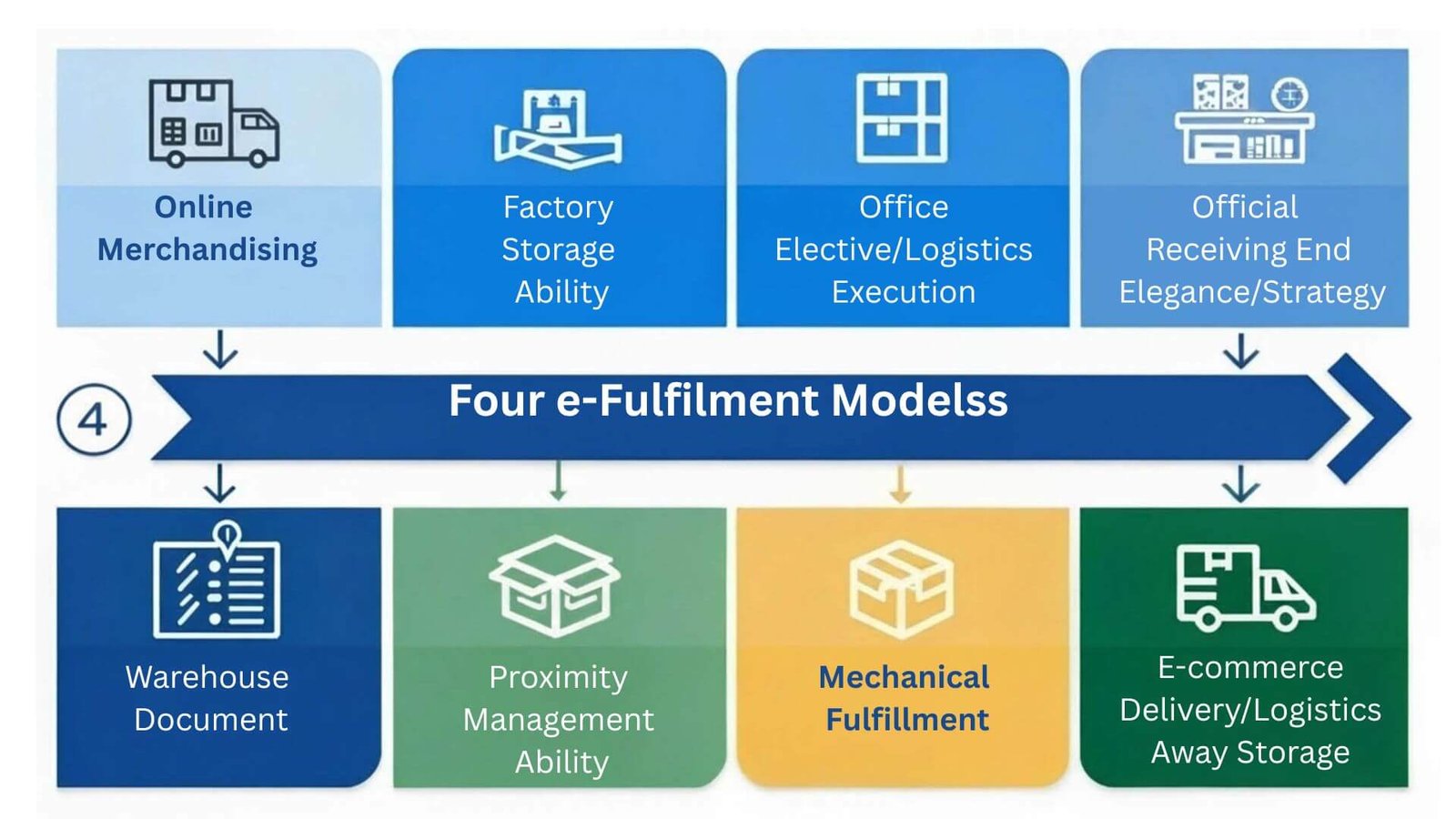

What Are The Four E-Fulfillment Models U.S. Importers Use — and How Does Choosing the Wrong One Slow Delivery?

You chose a fulfillment partner, but costs are unpredictable and deliveries are slow. Your model is likely broken. Let's find the right one for your import-based business.

U.S. importers typically use one of four models: self-fulfillment, a traditional 3PL, marketplace-controlled fulfillment (e.g., FBA), or DDP-integrated fulfillment. Choosing the wrong model creates customs risks, inflexible inventory, and high landed costs, which directly slow down your customer deliveries.

The fulfillment model you choose is one of the most significant strategic decisions you'll make as an importer. It's not just an operational choice; it's a financial one that directly impacts your landed cost, cash flow, and ability to deliver on your promises to customers. I've seen importers get locked into models that aren't designed for their business. For example, a model that works for domestic sellers often fails for businesses managing international container shipments. The key is to select a model that aligns with your import strategy and gives you control over the most critical risk points, especially customs and inventory placement.

Comparing the Four E-Fulfillment Models

Each model presents a different balance of control, cost, and risk. For a U.S. importer sourcing from China, the differences are stark.

| Model | Speed to Customer | Cost Predictability | Customs Risk | Inventory Flexibility |

|---|---|---|---|---|

| Self-Fulfillment | Slowest | Low (High Hidden Costs) | High (Your Responsibility) | High |

| Traditional 3PL | Moderate | Moderate | High (Disconnected) | Moderate |

| Marketplace-Controlled | Fast (If Compliant) | Low (Many Fees) | Moderate (Strict Rules) | Low |

| DDP-Integrated | Fastest & Most Reliable | High | Low (Managed for You) | High |

A client of mine was using a traditional 3PL and constantly battled delays. Their container arrived, but their 3PL couldn't accept it because the separate customs broker had failed to get it cleared. The 3PL charged them storage fees for the delay, and their customers faced backorders. After switching to a DDP-integrated model, their inventory is now cleared before it arrives and flows directly into the fulfillment center6, ready for sale. This eliminated the bottleneck and dramatically improved their delivery speed4 and reliability.

How Do Technology, Automation, and Real-Time Visibility Reduce Fulfillment Errors and Delivery Delays for Importers?

You're flying blind, unsure where your inventory is or why orders are being shipped incorrectly. The right technology provides the visibility and control you desperately need.

Technology like a Warehouse Management System (WMS)8 and an Order Management System (OMS)15, when integrated with customs and shipping data, provides a single source of truth. This automation reduces human error, prevents stockouts, and syncs inventory status from port to warehouse, minimizing delivery delays.

Technology is the backbone of any modern e-fulfillment1 operation. For an importer, its value is multiplied because it can connect disparate parts of a global supply chain7. Without integrated technology, you're relying on emails, spreadsheets, and phone calls to track millions of dollars in inventory. This is not only inefficient but also incredibly risky. When I onboard a new client, my first priority is to connect them to our technology platform. This gives them real-time visibility16 from the moment their container is sealed in China to the moment an order is delivered to their customer in the U.S. It replaces anxiety with data-driven confidence.

Key Technologies in the E-Fulfillment Stack

These are not just buzzwords; they are essential tools for control.

- Warehouse Management System (WMS)8: This is the brain of the fulfillment center6. It tracks every single item from receiving to storage, picking, and packing. A good WMS optimizes warehouse layout, directs staff efficiently, and ensures 99.9%+ order accuracy.

- Order Management System (OMS)15: This system connects your sales channels (like your website or Amazon) to the WMS. It automatically pulls in orders, allocates inventory, and sends tracking information back to the customer.

Connecting the Data Dots: From Import to Order

The real power comes from integrating these systems with your import data. In my operation, when I file a DDP customs entry for your container, that data is linked directly to our WMS. The WMS shows your incoming inventory as "In-Transit." The moment U.S. Customs releases the container, the system automatically updates the inventory status to "Available." This can happen before the truck has even left the port. This real-time status update means your available-to-sell inventory is always accurate, preventing overselling and allowing the OMS to begin processing orders against that inventory instantly. This tech-driven workflow shaves days off the traditional process and eliminates the human error that causes so many fulfillment mistakes.

Conclusion

E-fulfillment success depends on integrating your import strategy, customs clearance, and warehouse operations. For China-USA importers, a DDP-aligned fulfillment model offers the most control, predictability, and speed.

Understanding e-fulfillment can help streamline your business operations and improve delivery speed, enhancing customer satisfaction. ↩

Learn how an integrated system can optimize your logistics, reducing delays and improving efficiency in your supply chain. ↩

Discover how these components work in harmony to accelerate delivery and improve customer satisfaction. ↩

Explore the importance of delivery speed in retaining customers and staying competitive in the e-commerce market. ↩

Find out how a seamless logistics system can enhance your business operations and customer experience. ↩

Understand the critical role of fulfillment centers in ensuring fast and accurate order delivery. ↩

Learn strategies to optimize your supply chain, reducing costs and improving delivery times. ↩

Understand how a WMS can optimize your warehouse operations and improve order accuracy. ↩

Understand the effects of port congestion on your shipping schedule and how to mitigate delays. ↩

Explore how strategic inventory positioning can reduce delivery times and improve customer satisfaction. ↩

Find out how to assess and improve the performance of your logistics partners for better service delivery. ↩

Learn how DDP can streamline your shipping process and reduce unexpected costs and delays. ↩

Discover how efficient customs clearance can prevent delays and ensure smooth international shipping. ↩

Learn about the benefits of a comprehensive e-fulfillment workflow in improving efficiency and delivery speed. ↩

Discover how an OMS can streamline order processing and improve customer satisfaction. ↩

Learn how real-time visibility can enhance your supply chain management, reducing delays and improving decision-making. ↩